Welding Program

Gardena Campus

Hybrid

Format

10 Months

Approximate Length§

9

Course Modules

No

Includes Externship

Request More Information

Next Classes Start February 25, 2026¶

*High school diploma or equivalent required for enrollment.

About This Program

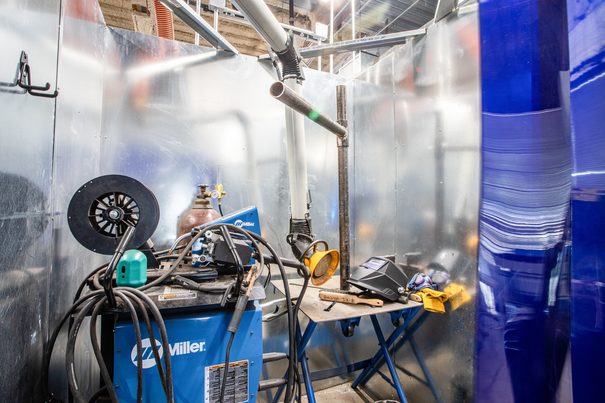

Learn the procedures, develop the skills, and gain the hands-on experience needed to start a rewarding new career by enrolling in the Welding program at UEI College in Gardena. At UEI College, you will have the opportunity to learn concepts and theories on your schedule online as well as put those concepts to practice in our real-simulation Welding Labs using real equipment you would use in the field. In our welding labs, students are taught multiple types of welding techniques using various professional-grade systems, including gas metal arc welding, flux core arc welding, oxyacetylene cutting, and so on. Other courses teaching safety, efficiency, reading blueprints, the identification of metals, and basic shop skills will further prepare you for an entry-level industrial or manufacturing career in as little as 10 months.

Course List

Career Outcomes

As a graduate of the program, you may qualify for the following positions:

- Assembly Line Brazer

- Braze Operator

- Brazer

- Brazing and Machine Setters

- Fabrication Welder

- Finishing Technician

- Maintenance Welder

- MIG Welder (Metal Inert Gas Welder)

- Robot Operator

- Solderer

- Spot Welder

- TIG Welder (Tungsten Inert Gas Welder)

- Welder / Welder Fitter

Gardena Campus Details

Campus:

UEI College - Gardena

Address:

661 W. Redondo Beach Blvd.

Gardena, CA 90247

Map

Phone:

(424) 286-9990

Campus Hours:

Monday 8:00 AM – 8:00 PM

Tuesday 8:00 AM – 8:00 PM

Wednesday 8:00 AM – 8:00 PM

Thursday 8:00 AM – 8:00 PM

Friday 8:00 AM – 5:00 PM

Saturday Closed

Sunday Closed

Accreditation:

UEI College - Gardena is accredited by the Accrediting Commission of Career Schools and Colleges (ACCSC)

Year Opened:

2011

Classes Starting:

February 25, 2026¶

Programs Offered at UEI College Gardena

Institutional Accreditation

UEI College Gardena is accredited by the Accrediting Commission of Career Schools and Colleges (ACCSC) - an accrediting agency recognized by the U.S. Department of Education.

This accreditation reflects our commitment to providing quality education that meets or exceeds standards. We want our students to feel confident in the education they receive.

Resources

How to Become a Welder?

If you are interested in becoming a welder, you've come to the right place. This guide will provide you with the step by step process you need to take to become a welder. Enroll in UEI College's Welding Program to begin a new, entry-level career in the welding field.